Understanding Grain Drying Equipment: A Key Component in Modern Agriculture

In the dynamic world of agriculture, grain drying equipment plays a crucial role in ensuring the quality and market value of harvested grains. By minimizing moisture content, this essential farm machinery helps farmers preserve their harvest for longer periods. In this comprehensive guide, we will delve into the world of grain drying equipment, discussing its types, benefits, and best practices.

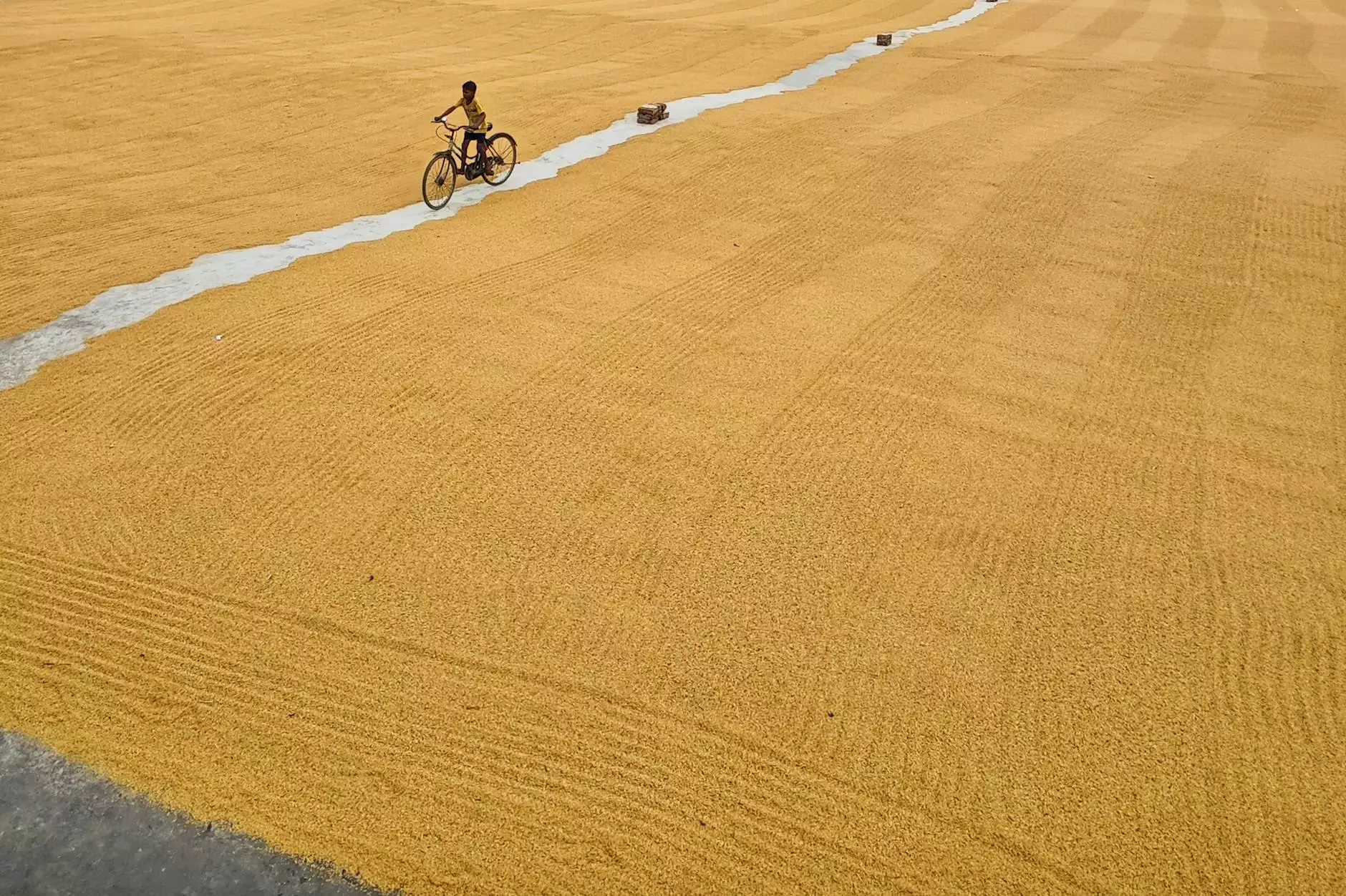

The Importance of Grain Drying

The drying process is crucial after the harvest. High moisture levels can lead to: - Mold and Spoilage: Excess moisture promotes fungal growth, rendering grains unusable. - Decreased Shelf Life: Moist grains experience shorter storage periods leading to potential losses. - Quality Deterioration: Moldy grains lose their nutritional value and market quality.

Types of Grain Drying Equipment

There are various types of grain drying equipment available, each serving specific needs and levels of operation. Here are the most common types:

1. Batch Dryers

Batch dryers operate by drying a specific amount of grain at one time. After loading, the grain is dried and must be removed before the next batch can be processed. These dryers are typically used in small-scale operations or on farms with limited quantities of grain.

2. Continuous Flow Dryers

Unlike batch dryers, continuous flow dryers allow grains to pass through the dryer while being consistently heated and dried. This type is more efficient for larger operations since it can handle a steady influx of grain.

3. Tower Dryers

Tower dryers are vertical structures that utilize gravity to facilitate the grain drying process. With different design features, such as multiple drying layers, they offer optimized drying efficiency and are suitable for large-scale farms.

4. In-bin Dryers

In-bin drying utilizes the existing grain storage bins for drying. Heated air is circulated within the bin, allowing moisture to escape the grain while keeping it in storage. This method is convenient for farmers who wish to minimize equipment usage.

Factors Influencing Grain Drying Equipment Choice

Selecting the right grain drying equipment for your operation involves considering several critical factors:

- Capacity Needs: Understand the volume of grain you process and choose equipment that handles your estimated harvest efficiently.

- Moisture Content: Different grains may require specific moisture reduction strategies. Gauge the initial moisture content to select suitable equipment.

- Energy Efficiency: Look for models that optimize energy consumption, as drying can consume a significant amount of power.

- Operational Cost: Factor in the purchase price, maintenance costs, and energy consumption to determine the total cost of ownership.

- Space Availability: Ensure that you have adequate space for installation and operation of the selected drying equipment.

Benefits of Investing in Quality Grain Drying Equipment

Investing in high-quality grain drying equipment can transform your farming practices and significantly benefit your bottom line:

1. Improved Grain Quality

By controlling the drying process, equipment allows for optimal grain moisture levels, enhancing its overall quality and marketability.

2. Increased Shelf Life

Properly dried grains boast longer storage times, reducing the risk of spoilage and loss due to pests and mold.

3. Higher Yield and Profitability

Minimizing spoilage and maximizing quality leads to better yields and profitability, helping farmers recover their investments sooner.

4. Enhanced Efficiency

The right equipment optimizes the drying process, ensuring a quicker turnaround between harvest and storage. This efficiency is vital during peak harvest times.

Best Practices for Operating Grain Drying Equipment

To make the most of your grain drying equipment, adhere to the following best practices:

1. Regular Maintenance

Routine inspections and maintenance keep your equipment in top condition, preventing unexpected downtimes and costly repairs.

2. Monitor Moisture Levels

Utilize moisture meters to keep track of grain moisture content accurately. This information ensures that you do not over or under-dry your harvest.

3. Optimize Airflow

Ensure that air is evenly distributed throughout the drying system. This will help achieve a uniform drying process, resulting in better-quality grains.

4. Follow Manufacturer Guidelines

Always adhere to the equipment manufacturer’s guidelines for operation, maintenance, and safety to ensure longevity and efficiency.

The Future of Grain Drying Technology

The landscape of agricultural technology is ever-evolving, and grain drying is no exception. With advancements in technology, future grain drying equipment will likely feature:

1. Automation

Automation in grain drying processes increases efficiency and allows for better management of grain conditions throughout the drying cycle.

2. Energy Efficiency

New technologies aim to minimize energy consumption further, leveraging renewable energy sources and innovative heating methods.

3. IoT Integration

Using Internet of Things (IoT) technology, farmers will be able to monitor conditions in real-time, adjusting parameters remotely for optimal drying.

4. Data-Driven Decision Making

With the incorporation of advanced data analytics, farmers will have more insights into their drying processes, allowing for better strategic planning and execution.

Conclusion

In conclusion, grain drying equipment is an indispensable asset for today’s agricultural practices. By investing wisely in high-quality equipment and adhering to best practices, farmers can ensure their harvests are preserved at optimal quality, which translates into better market value and profitability. The ongoing advancements in technology promise to enhance the capabilities of grain drying systems further, making it an exciting time for the agricultural industry.

For any farming operations looking for reliable grain drying equipment, consider exploring the offerings from TSGC INC. and discover how tailored solutions can meet your grain drying needs while ensuring superior quality and efficiency.