Maximize Performance: Buy Solenoid Valves with Confidence

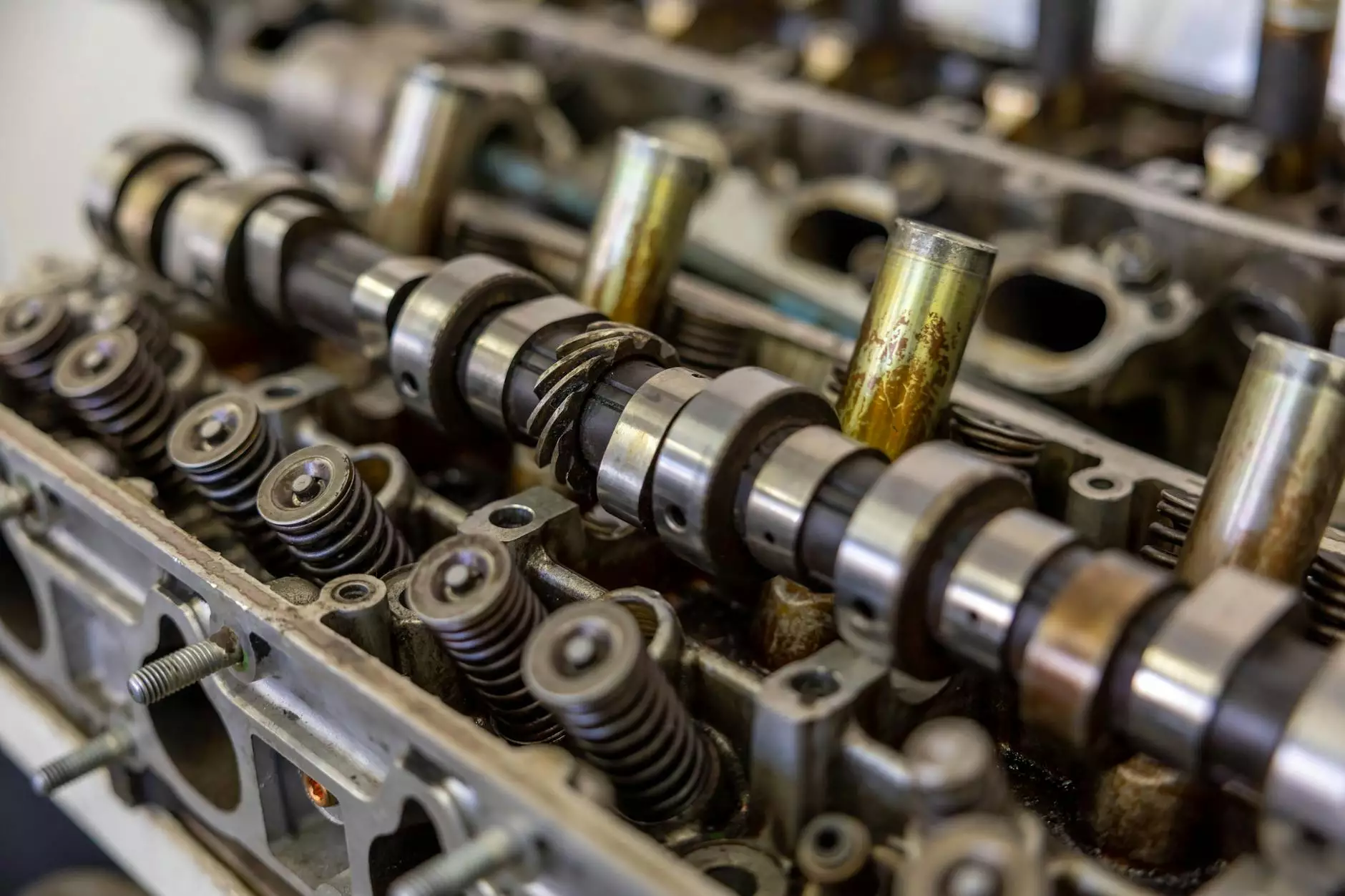

In the world of diesel engine parts, certain components play pivotal roles in ensuring optimal performance and efficiency. One such critical component is the solenoid valve. As industries increasingly turn towards automation and precision engineering, the demand for high-quality solenoid valves has surged. If you're looking to buy solenoid valves, understanding their functions, applications, and where to source them from is crucial. This comprehensive guide will illuminate every aspect you need to consider when purchasing solenoid valves.

The Importance of Solenoid Valves

Solenoid valves are electromechanical devices that control the flow of liquids or gases in a system. They serve as on-off switches that manage fluid movement by opening or closing in response to electrical signals. Their significance spans across various industries, including:

- Aerospace - Used in fuel systems and control systems.

- Automotive - Critical for fuel injection systems in internal combustion engines.

- Manufacturing - Used in process control for fluid handling.

- HVAC - Regulate the flow of refrigerant or air in heating and cooling systems.

How Do Solenoid Valves Work?

Understanding the operation of solenoid valves is essential when considering a purchase. A solenoid valve consists mainly of the following components:

- Coil: When electrical current flows through the coil, it generates a magnetic field.

- Plunger: The magnetic field moves a plunger or armature that opens or closes the valve.

- Body: Contains the inlet and outlet ports for the fluid.

- Spring: Keeps the valve closed when de-energized.

When you buy solenoid valves, it’s crucial to select the right type based on your operational needs. Options include normally closed, normally open, and directional control valves.

Applications of Solenoid Valves

Solenoid valves find applications in various scenarios. Here are some common uses:

- Fuel Supply: In diesel engines, solenoid valves control fuel flow, improving fuel efficiency and engine performance.

- Water Management: Used in irrigation systems to automate water supply, enhancing agricultural efficiency.

- Industrial Automation: Manage pneumatic or hydraulic systems in manufacturing processes.

- Building Systems: Control air conditioning and heating systems for optimal energy use.

Choosing the Right Solenoid Valve

When you decide to buy solenoid valves, consider the following factors to ensure you make an informed choice:

1. Medium Type

Determine whether the valve will handle air, water, or oil, as different materials and designs are required for different mediums.

2. Pressure Rating

Ensure the valve can withstand the operating pressure of your system. Solenoid valves come with various pressure ratings, and selecting the appropriate one is critical to prevent failures.

3. Voltage Rating

Solenoid valves operate on different voltage ratings (e.g., AC or DC voltages). Ensure compatibility with your power source.

4. Material Considerations

Consider the body material, as it impacts the valve's resistance to corrosion and temperature variations. Common materials include:

- Brass: Commonly used for water applications.

- Stainless Steel: Ideal for harsh environments or corrosive substances.

- Plastic: Lightweight and resistant to chemicals, suitable for various applications.

5. Connection Type

Different solenoid valves come with various connection sizes and types such as threaded, flanged, or push-to-connect. Ensure the connection type matches your existing systems.

Where to Buy Solenoid Valves

Now that you know what to look for when you buy solenoid valves, the next step is finding a reputable supplier. client-diesel.com stands out as a reliable source for diesel engine parts and spare parts suppliers. Here are some reasons to consider sourcing from them:

- Quality Assurance: They provide high-quality solenoid valves that meet industry standards.

- Diverse Range: A wide selection of solenoid valves designed for various applications and systems.

- Expert Guidance: Knowledgeable staff can assist you in selecting the right product for your needs.

- Competitive Pricing: Enjoy cost-effective solutions without compromising on quality.

Advantages of Quality Solenoid Valves

Investing in high-quality solenoid valves has numerous advantages:

- Reliability: Quality valves have a longer lifespan, reducing downtime and the frequency of replacements.

- Efficiency: Properly functioning solenoid valves contribute to overall system efficiency, enhancing operational performance.

- Safety: High-quality valves reduce the risk of leaks and failures, ensuring safe operation.

- Versatility: Well-made solenoid valves can adapt to various applications, making them a worthwhile investment.

Maintenance and Care for Solenoid Valves

Proper maintenance of solenoid valves is crucial for ensuring longevity and optimal performance. Here are some tips to keep in mind:

1. Regular Inspections

Conduct routine checks to ensure the valves are functioning correctly. Look for signs of wear or corrosion.

2. Cleanliness

Keep the surrounding area clean to prevent debris from entering the valve and affecting its performance.

3. Proper Shutdown Procedures

When shutting down systems, ensure solenoid valves are properly closed to prevent pressure surges that can cause damage.

4. Follow Manufacturer Guidelines

Adhere to maintenance schedules and procedures recommended by the manufacturer to ensure optimal functioning.

In Conclusion

In summary, solenoid valves are vital components in various industries, including automotive, manufacturing, and HVAC. When you decide to buy solenoid valves, take the time to understand your requirements, evaluate options, and choose suppliers like client-diesel.com who offer reliable, quality products. With the right investment in solenoid valves, you are bound to enhance operational efficiency, safety, and performance across your systems. Investing in quality is investing in future success, so make your purchase count!